Carbon dioxide dry ice cleaning machine

The CO2 dry ice cleaning machine is a new type of cleaning equipment that uses CO2 dry ice particles as a cleaning medium to achieve surface cleaning through high-speed spraying. This cleaning technology has gradually attracted attention from various industries in recent years and is widely used due to its environmental protection, efficiency, and safety characteristics. This article will provide a detailed introduction to the working principle, advantages, application areas, and usage precautions of the CO2 dry ice blasting machine.

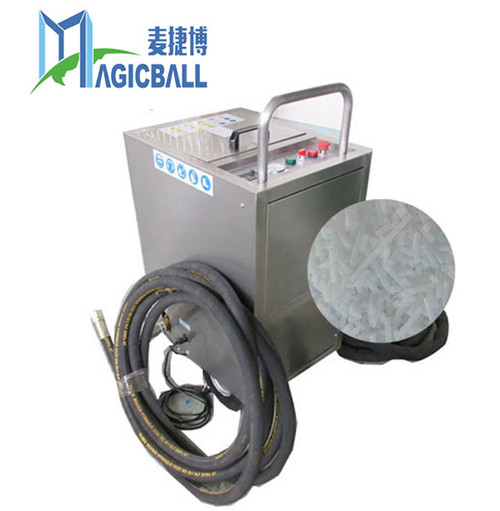

Understanding the working principle of carbon dioxide dry ice blasting machine is crucial. The equipment mainly consists of a spraying system, a compressor, a dry ice chamber, and a control system. During the working process, dry ice particles are accelerated to high speed by the compressor and sprayed onto the surface that needs to be cleaned through the nozzle. When dry ice particles come into contact with dirt, they instantly absorb heat and sublime into gas, producing an airflow that quickly blows the dirt away from the surface. This process not only effectively removes surface dirt, but also does not cause damage to the cleaned object, as dry ice does not leave any residue during the sublimation process.

The advantages of carbon dioxide dry ice cleaner are very obvious. The cleaning process is waterless and does not require the use of chemical cleaning agents, so it does not produce wastewater or harmful substances, which meets environmental protection requirements. Due to the fact that dry ice does not leave any residue during sublimation, the cleaned surface is clean and tidy. Dry ice cleaning is very fast and suitable for large-scale cleaning operations, which can greatly improve work efficiency. Dry ice is very friendly to most materials, including metals, plastics, glass, etc., reducing the risk of damage during the cleaning process.

In terms of application fields, the use of carbon dioxide dry ice cleaner is very extensive. Industrial manufacturing is one of its main application areas, especially in industries such as machinery, electronics, and automobiles. Dry ice cleaning can effectively remove oil stains, dust, and other dirt generated during the production process. The food processing industry also uses dry ice cleaning to maintain the hygiene of equipment and production environment, avoiding the impact of chemical residues on food safety. Dry ice cleaning is widely used in the fields of construction and maintenance to clean walls, equipment, and pipelines, effectively removing coatings, paints, and corrosive substances.

Although CO2 dry ice cleaning machines have many advantages, there are still some precautions to be taken during use. Operators should wear appropriate protective equipment, including gloves, goggles, and protective clothing, when using the equipment to ensure safety. The storage and handling of dry ice should follow relevant regulations to avoid frostbite caused by low temperatures. During the cleaning process, attention should be paid to controlling the spray pressure and distance to avoid damage to the object being cleaned. Try to carry out cleaning operations in a well ventilated environment to avoid the impact of high concentrations of carbon dioxide gas on human health.

In summary, the CO2 dry ice cleaning machine is an efficient and environmentally friendly cleaning equipment suitable for the cleaning needs of various industries. With the advancement of technology and the improvement of environmental awareness, more and more enterprises are paying attention to and applying this new cleaning technology. Although safety and operational standards need to be taken into account during use, overall, the advantages of dry ice cleaning machines make them an important tool in the modern cleaning industry. In the future, with the continuous development of technology, the application of carbon dioxide dry ice blasting machines will become more widespread and bring more efficient cleaning solutions to various industries.